Tubing Anchors

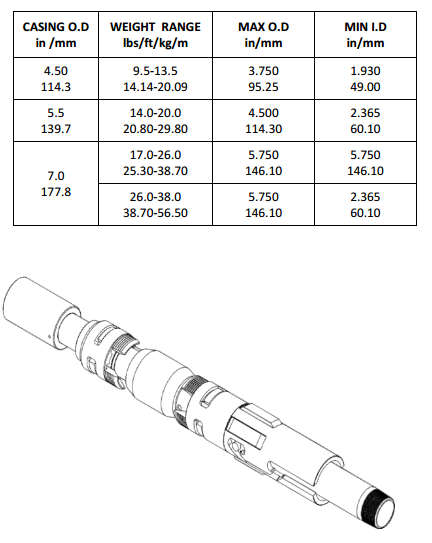

TCI Dual Quarter Anchor Catcher (TDQAC)

The TQDA is a rugged anchor-catcher that operates with minimum (less than a 1/4 turn) tubing string rotation to set or release. The no torque option resists right hand rotation of the tubing string while set, yet allows the string to rotate the ¼ turn required to release.

- Right hand set and release tubing anchor/catcher

- Wickered or carbide tipped slips available

- Adjustable safety release to 60000 #

- Drag Blocks

TCI Quarter Dual Anchor (TDQA)

TCI Quarter Dual Anchor (TDQA)

The TQDA is a rugged anchor-catcher that operates with minimum (less than a 1/4 turn) tubing string rotation to set or release. The no torque option resists right hand rotation of the tubing string while set, yet allows the string to rotate the ¼ turn required to release.

- Right hand set and release tubing anchor/catcher

- Wickered or carbide tipped slips available

- Adjustable safety release

- Stainless steel drag springs

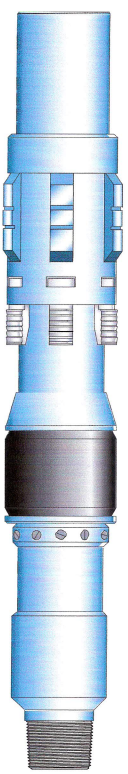

TCI “QT” Tension Anchor

TCI “QT” Tension Anchor

The TCI QT Tension Anchor is a compact, rugged, economical, single grip tension anchor, used to place tubing into tension, with a quarter turn to the right. TCI QT Tension Anchor can be released by applying compression to below set depth.

Features:

- 1/4 Trun Right Hand Set

- Sets securely in any grade casing

- Large Bore, smaller OD, for quicker running , or retrieval

- Drag BLocks for optimal setting control

- Compression or Emergency shear release

- Adjustable shear release from 5,000 to 50,000 lbs

- Can replace spacer with element

Specifications:

- 5 1/2 inch 14-17 lb/ft 2-7/8 EU 8 Rd

- 7 inch 17-26 lb/ft 2-7/8 EU 8 Rd

TCI “QT” Tension Anchor

TCI “QT” Tension Anchor

The TCI QT Tension Anchor is a compact, rugged, economical, single grip tension anchor, used to place tubing into tension, with a quarter turn to the right. TCI QT Tension Anchor can be released by applying compression to below set depth.

Features:

- 1/4 Trun Right Hand Set

- Sets securely in any grade casing

- Large Bore, smaller OD, for quicker running , or retrieval

- Drag BLocks for optimal setting control

- Compression or Emergency shear release

- Adjustable shear release from 5,000 to 50,000 lbs

- Can replace spacer with element

Specifications:

- 5 1/2 inch 14-17 lb/ft 2-7/8 EU 8 Rd

- 7 inch 17-26 lb/ft 2-7/8 EU 8 Rd

TCI HC “QT” Turn Tension Anchor

TCI HC “QT” Turn Tension Anchor

The TCI HC QT ¼ Turn Tension Anchor is designed to anchor the tubing string from movement in tension or Rotation. The benefits of placing the tubing string in tension, is to ensure that the tubing follows the rod string, as close as possible, to minimize rod wear.

Benefits:

The TCI HC QT ¼ Turn Tension Torque Anchor has additional features incorporated into the design.

- Solid high strength slip design

- Allows coil tubing to pass by the tool

- Open design for Gas and Sand to by-pass

- Hardened drag blocks for longer life

- Inconel springs for H2S and CO2 resistance

- Simple setting and releasing procedures

- Teflon Coated Mandrel for H2S and CO2, While Maintaining mandrel strength

- Can be used to carry Capillary Cable Down hole.

Operation:

The TCI HC QT ‘¼ Turn’ Tension Torque Anchor is threaded onto the tubing string above or below the Pump. The Anchor is run to the setting depth, lift the Tubing String approximately 1.0” and turn the Tubing String to the right, ‘¼” Turn’ at the Tool, and then pull straight up, to set the Anchor in the Casing. The anchor is released by moving the Tubing String down and rotating the tubing in the opposite direction. Or, it can be released, by pulling tension on the tubing string, above the shear value. The anchor can either be moved to a different location, or pulled from the well.

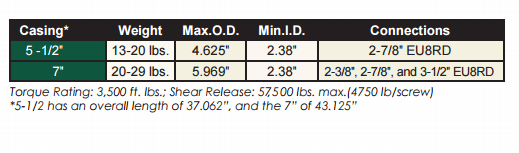

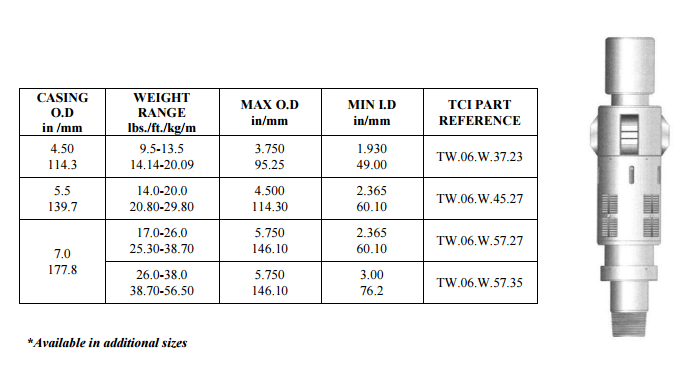

TCI Tubing Anchor/Catcher (TTAC)

The TCI TAC is a heavy duty mechanical tool that is designed to anchor the tubing in tension. The anchor/catcher prevents movement of the tubing during pumping and will hold it stationary should part occur. The anchor also increases pump efficiency and reduces rod and tubing wear.

Features:

- Heavy duty construction

- Enclosed slips and heavy duty drag blocks

- Rotational set and release

- Secondary shear release field adjustable.

- Left and right hand set options available

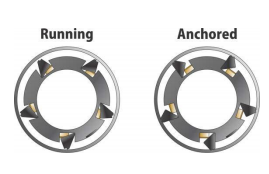

TCI Torque Anchor

The TCI Torque Anchor® has been developed to provide a simple and reliable solution for tuning back-off when progressing cavity pumps are used. The unique patented design allows for easy running and retrieval in a variety of down hole conditions including:

The TCI Torque Anchor® has been developed to provide a simple and reliable solution for tuning back-off when progressing cavity pumps are used. The unique patented design allows for easy running and retrieval in a variety of down hole conditions including:

- Deep Wells

- Horizontal Wells

- Heavy Oil

Applications:

- Tuning back-off for progressing cavity pump applications.

- Deep wells and horizontal wells

- Heavy oil situations

Features & Benefits:

- Robust, reliable design

- Spring-loaded anchor blocks

- Simple to use

The Dynamic Torque Anchor® allows for full bore configuration, maximum bypass in the annulus and its function is not affected by the presence of produced sand.

The TCI Torque Anchor® uses wedge shaped anchoring blocks which bite into the casing wall when right hand torque is generated in the tubing string. These anchoring blocks are spring loaded so that transfer of torque to the casing is immediate (clockwise) and the tubing string may be freely rotated to the left (counter- clockwise). Due to the original design of the anchoring blocks, only a simple engaging and disengaging procedure is required.

The running procedure of the TCI Torque Anchor® is as simple as the design itself. The anchor is installed below the pump and can be run in and out of the well freely. When the anchor has reached the required depth, the application of approximately 300ft-lbs right hand torque, will securely engage the anchoring blocks to the casing wall. The setting torque may now be locked in and the pump operation started.

To disengage the anchor, simply stop the pump operation and relax initial setting torque

What type of tubing swivel do I need?

Two–Way Swivel:

The Two-Way Tubing Swivel is designed to allow a torque anchor to be set in position. Shear screws in the Two-Way swivel allow the anchor to be set and when sufficient torque is applied, the swivel shears and the Two-Way will now rotate left or right. The Two-Way swivel cannot unset the anchor through rotation. A torque anchor must be pulled to be unset. Typically, TwoWay swivels and tension anchors are not used together as tension anchors need rotation to be unset.

One-Way Swivel:

The One-Way Tubing Swivel is designed to allow a right hand set torque or tension anchor to be set into position. Shear screws in the One-Way swivel allow the anchor to be set and when sufficient right hand torque is applied, the swivel shears and the One-Way swivel will now rotate to the right only. Any left hand rotation will lock the swivel. Once the anchor is to be unset, left hand torque will engage the ratcheting mechanism in the One-Way swivel and allow left hand torque to be applied to the anchor to unset it.

Clutched Swivel:

The Clutched Tubing Swivel is designed to allow a right or left hand set tension anchor to be set into position. Shear screws in the Clutched swivel allow the tension anchor to be set and when sufficient tension is applied, the swivel shears and the Clutched swivel will now rotate left or right. Sufficient tension must be maintained to ensure the Clutched swivel remains free wheeling. Once the tension anchor is to be unset, weight must be put on the anchor and depending on the type of tension anchor, right or left hand torque can be applied to unset the tension anchor. Typically, Clutched swivels and torque anchors are not used together.

Resettable Clutched Swivel:

The Resettable Clutched Tubing Swivel is designed to allow a right or left hand set tension anchor to be set into position. When sufficient tension is applied, the Resettable Clutched swivel disengages and will now rotate left or right. Sufficient tension must be maintained to ensure the Resettable Clutched swivel remains free wheeling. The design of the Resettable Clutched Swivel allows for the tension anchor to be repositioned without the need to bring to surface to replace shear screws. Putting weight on the tension anchor will reset the Resettable Clutched Swivel and allow for the anchor to be repositioned. The Resettable Clutch Swivel is now ready to allow the tension anchor to be set again into a new position.

TCI Spirit Gas Separator

TCI Spirit Gas Separator

Description:

- 40′ long, creating an artificial sump that allows for longer pumping periods when a well is surging gas

- Patented “Emulsion Breaking” baffle system.

TCI Spirit Jet PC Pump Gas Separator

TCI Spirit Jet PC Pump Gas Separator

The TCI Premium Spiral Jet (PSJ) PC Pump Gas Separator offers significant improvements to the gas separation of fluid prior to entering progressive cavity pumping systems.

Some of the main features are:

- Improved inlet configuration that enhances the breakdown of sand and heavy oil clumps.

- Improved gas separation through increased velocity.

- Circular spiral flow passages eliminate turbulence and help to organize the flow for increased separation.

- Improved gas exhaust system ensures that separated gas will not remix with fluids about to enter the progressive cavity pump.

- Slimhole design for more annular space.

- Due to the improved inlet configuration, the PSJ Gas Separator will act with the same efficiency in both light oil and heavy oil applications.

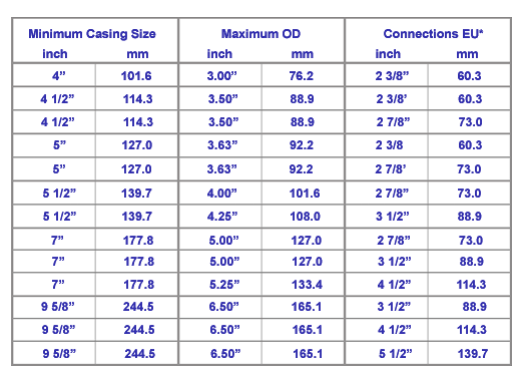

TCI Rod Pump Gas Separator

TCI Rod Pump Gas Separator

The TCI Premium Rod Pump Gas Separator is designed to separate free gas from wellbore fluids prior to entering the pump, eliminating many pump related problems such as gas locking, decreased production rates and reduced efficiencies.

The Rod Pump Gas Separator is installed directly below the rod pump making the pump intake through the gas separator. During the upstroke of the pump, the fluid mixture is drawn into the gas separator through ports at the top of the tool. During the down stroke or “quiet time”, the free gas separates from this fluid mixture and exhausts out of these same ports on the gas separator. The remaining liquid in the gas separator is drawn into the pump through ports at the bottom of the inner dip tube during the next upstroke. Therefore, the upstroke of the pump draws separated liquids into the pump at the same time a new fluid mixture is being drawn into the gas separator ready for gas separation during the next “quiet time”.

Our Rod Pump Gas Separators are engineered to allow sizing to be as simple as determining your pump volumes and choosing a separator size that will accommodate the maximum expected pump rate. This design also allows for multiple units to be run in tandem, allowing for higher fluid production.

TCI Premium ALS offers the Rod Pump Gas Separator in either Regular Steel Housing or Stainless Steel Housing configurations. The Stainless Steel housing offers superior protection in corrosive environments and greatly extends the life of the tool.

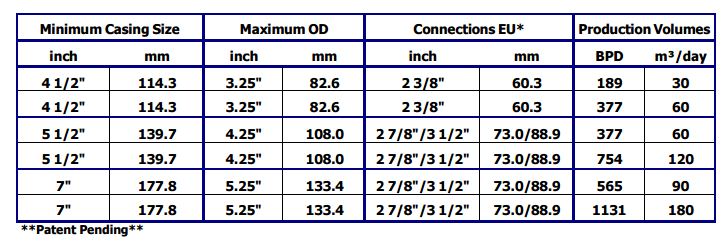

Premium Weighted Intake Rod Pump Gas Separator

The Premium Weighted Intake Rod Pump Gas Separator is similar to our Rod Pump Gas Separator with an added feature that allows it to be installed in highly deviated Rod Pumping wells. The Weighted Intake Rod Pump Gas Separator has slots cut into the top of the housing rather than top sub ports and these slots allow free inflow of the fluid mixture and exhaust of the separated gas.

Installed on the flow tube inside the housing is a weighted intake sub that orients the fluid intake to the bottom of the housing, ensuring only fluids are drawn into the pump, regardless of the gas separator angle or position.

Where higher production volumes are required, we also manufacture an “Extended Volume” Weighted Intake Rod Pump Gas Separator. Also, the Weighted Intake Rod Pump Gas Separator can have either a bull plug on the bottom for typical installs or with a special coupling that allows a 6’ housing (or a length of tubing) to be attached to the bottom of the tool to act as a cellar for debris such as sand or coal fines.

As with our Rod Pump Gas Separators, the Weighted Intake Rod Pump Gas Separator is also offered with Stainless Steel Housings as well as regular steel. The Stainless Steel housing offers extra protection in highly corrosive environments.

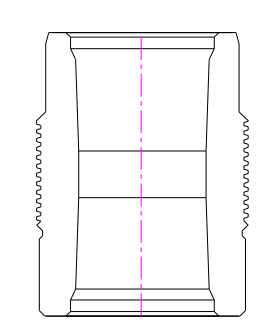

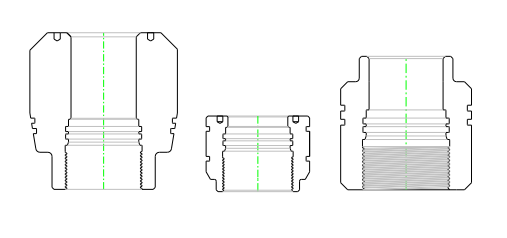

TCI Double Box Bushing Hanger

The Techno Completions Inc. hanger provides a simple and safe method of applying and removing tension from a tubing string, effective when used with any packer or anchor requiring tubing tension to actuate.

The TCI supplied double box bushing tubing hanger is a mandrel type hanger which consists of two separate pieces:

The TCI supplied double box bushing tubing hanger is a mandrel type hanger which consists of two separate pieces:

- An inner bushing that has a box female tubing connection on the top and bottom, and an external acme thread.

- An outer mandrel (body) which can be manufactured to fit most tubing head profiles and sizes allowing for consistent and economical supply while providing an annular seal within the tubing head. (Some practical examples are represented in the images below)

Installation:

- 1.1 Calculate the amount of pre – stretch required.

- 1.2 Replace the last tubing coupling with the inner bushing and run it below the tubing head to the calculated amount of pre – stretch required.

- 1.3 Set the tool and apply the calculated pre – stretch plus the required overstretch. Please note that the over – stretch will vary depending upon the type of tubing head and outer mandrel.

- 1.4 Ensure the inner bushing is clean of debris and burrs. Coat the entire thread surface and seal area prior to makeup with clean grease or anti – seize compound.

- 1.5 Lower the outer mandrel on top of the inner bushing and rotate counter – clockwise (left hand thread)

- 1.6 Set the hanger assembly into the tubing head and engage the lockdown screws.

Retrieving:

- 2.1 Tighten handling joint of tubing into the top thread in the hanger

- 2.2 Lift the hanger assembly free, at least the over – stretch.

- 2.3 Rotate the outer mandrel clockwise to free from the inner bushing

- 2.4 The tubing may now be lowered through the mandrel to relieve any or all tension.