Service Tools

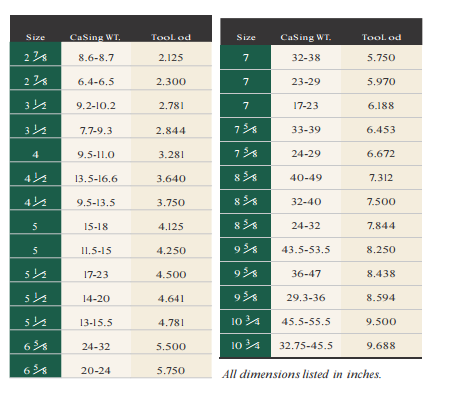

WLTC Retrievable Bridge Plug

The WLTC Retrievable Bridge Plug is designed to perform all tasks normally required of a tubing run packer-type bridge plug and can be quickly converted to run and set on wireline. It is designed to be rugged and compact (the 4-1/2” size is only 63 inches long).

When run on tubing, the WLTC can be set deep or shallow because the packing element system can be energized with compression or tension. This bridge plug will withstand high differential pressures from above or below, while its internal bypass valve is easily opened to equalize fully prior to release.

Activated slips are always on the low-pressure side with the WLTC design, ensuring that a tight pack-off is maintained. When run on tubing, a circulation passage through the tool reduces the need for swabbing by allowing fluid to bypass internally. When set, another passage allows effective washing of sand and debris above the elements, ensuring easy release and retrieval.

Standard equipment on the WLTC Retrievable Bridge Plug includes tungsten carbide-tipped slips and drag blocks, which are long-lasting and allow for easy setting in the hardest casings. T C I ’ s Spring Loaded Overshot is used to run (tubing set) and retrieve (tubing or wireline set) the WLTC Bridge Plug.

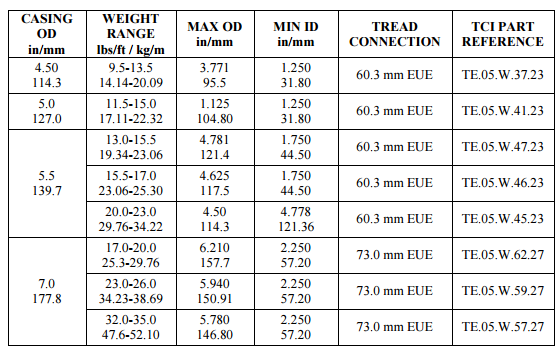

TCI CWRP Retrievable Bridge Plug

The TCI CWRP is a Retrievable bridge plug that can be run on electric wire line or in conjunction with a hydraulic setting tool on tubing. The plug is a compact, quick running bridge plug that features a three piece element with steel gauge rings. Bidirectional slips provide simple, affective anchoring to the casing. The pressure equalizing system allows the plug to be unset with a straight pull.

Features:

- Holds pressure from above and below.

- Three piece packing element systems provides for reliable, proven performance.

- Caged bidirectional slips for maximum performance.

- Manufactured from rugged alloy steel for optimum reliability in severe conditions.

- Balanced equalizing system.

- Pressure equalizes prior to releasing.

- Straight pull to release plug.

- Optional sand line or coil tubing retrieving (must be indicated to service rip before running).

- Cost effective.

- Differential pressures of 10,000 psi (69 Mpa)

TCI WR-CW Bridge Plug

The TCI WR-CW Bridge Plugs are a proven and reliable retrievable bridge plug. They are commonly used for zone or well isolation during fracturing , acidizing, cement squeezing , testing or up-hole/surface repair operations.

The double acting slips securely anchor the Bridge Plug against pressure differentials from above or below. The three element pack off design ensures reliable sealing at high pressures and temperatures .

The equalizing valve design allows pressure differential to be equalized before going through the upward releasing motion. No rotation is required to release either the WR or the CW Bridge Plug.

Wireline or Hydraulic Set:

- May be ran and retrieved on wireline, coil or jointed pipe.

- Three element system for reliable operation.

- Proven equalizing system for safe, reliable release.

- One piece, double acting slips

- Requires straight pull, no rotation to release.

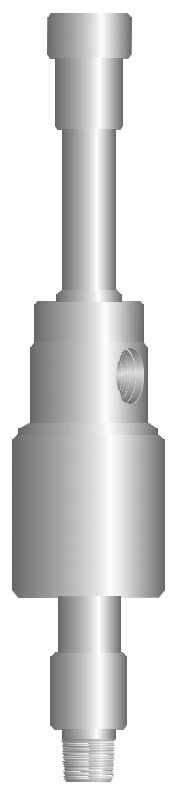

The TCI “K” Connector Valve

The TCI “K” Connector Valve is a high pressure mechanically operated valve used to convert a double grip retrievable packer to a bridge plug. The TCI“K” Connector design allows pressure to equalize above and below before the packer is released. The running retrieving tool is locked to the valve eliminating accidental separation.

Running: Run the bridge plug to depth and pick up holding left-hand torque, set down while maintaining left-torque (this will engage j-pin in locked position) and pick up holding left hand torque will release the running retrieving tool from the valve.

Retrieving: Circulate debris from top of Bridge Plug and lower retrieving tool until engaged. Apply right hand torque and pick up allowing pressure to equalize before proceeding with packer release.

- Equalizes pressure before packer is released.

- Bonded seals for repeated use under pressure.

- Safety dogs elimate accidental separation.

- Auto jay retieving tool for easy connecting.

- 10,000 psi pressure rating.

TCI Selective Cup Treating Tool (SCTT)

The TCI SCTT is a cup style selective treating tool. The tool is design for selective acidizing of predetermined perforating intervals. Interval length can vary from 0.3 m (12”) to any desired length by the addition of spacer tubing pup joints. A built in bypass makes the SCTT easy to run and retrieve. A drag block assembly provides a positive method for controlling the optional circulating valve. A retrievable dart is used to blank off the lower portion below the stimulation ports.

Features:

- Used to selectively acidize multiple intervals in a single run.

- Heavy duty reinforced casing cups.

- Backup cups for increased pressure rating.

- Large internal bypass making it easy to run and retrieve.

- Optional rotational circulating valve.

- Fluid control valve available for low pressure/ low fluid level wells.

- May be run with a swab packer assembly.

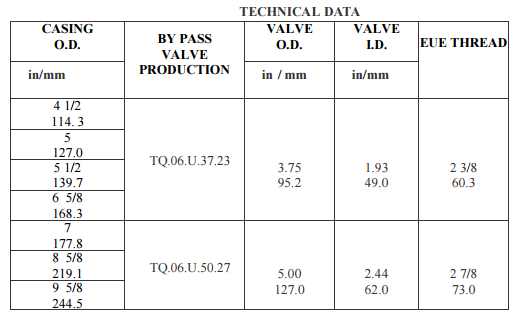

TCI By-Pass Valve

The TCI By-Pass Valve is a rotational circulating valve designed for use with the TCI SCTT Selective Tools. This valve opens or closes off communication between the tubing and the annulus.

The valve is used to bypass tubing fluid when running or retrieving Selective Tools, and if required can also be used for circulation of fluids.

The By-Pass Valve features a pressure balanced sleeve design which allows for easy operation of the valve under high differential pressures. Specially designed chemical and wear resistant seals ensure reliable and trouble free operation.

Exclusive to this valve are the Thrust Bearings which allow for easy operation under tension or compression loads.

Operation: The By-Pass Valve is opened by rotating 3 turns to the right and closed by rotating 3 turns to the left.

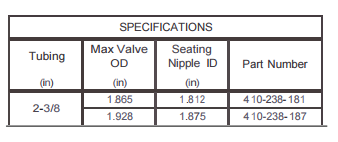

TCI MFCV Fluid Conrol Valve

The Model “M” Fluid Control Valve is a pressure activated valve used to provide, surface control over fluids. Particularly suited to injection wells with low reservoir pressures by supporting the hydrostatic head in the tubing.

Applications:

- Typically used in conjunction with a selective stimulation tool or straddle type packer to provide fluid control when selectively acidizing low fluid levels.

- Selective scale removal.

- Chemical treatments.

Features:

- Operates using differential pressure and is not dependent on well depth.

- Prevents loss of expensive chemical in low fluid level wells.

- Utilizes chemical and wear resistant seals to ensure problem free operation.

- Protects sensitive formations by holding displacement fluids in tubing.

- Sand line or wireline retrievable.

- Surface controlled by tubing pressure.

- Meters precise volumes of liquids.

Drag Assembly

TCI Drag Assembly

TCI Drag Assembly

The Drag Assembly is designed with Drag Blocks and Inconel Springs. It is commonly run with Selective Acidizing equipment to anchor the bottom hole assembly, thus enabling torque transmission to rotational valves.

The centralizing effect of the Drag Assembly increases tool life, especially in Cup Type Acid Tools.

TCI Collar Locator

TCI Collar Locator

The Mechanical Casing Collar Locator provides a simple and reliable method of locating Casing Collars with the Tubing String to correlate the tubing depth to the logged depth.

This tool is commonly run with Selective Acidizing Tool assemblies to locate the perforation depth. The Collar Locator is installed as an integral part of the Tubing String. To operate properly it must be installed above any Drag Block Assemblies or tools using Drag Blocks or Springs. The Collar Locator is designed to indicate the collars when moving the tubing up. Spring loaded pads on the Locator expand into the recess of the Casing Coupling. The additional force required to collapse the pads again in order to pass through the coupling, is indicated at surface.

The tubing may be rotated freely through the Collar Locator without having to rotate the pads in the casing.

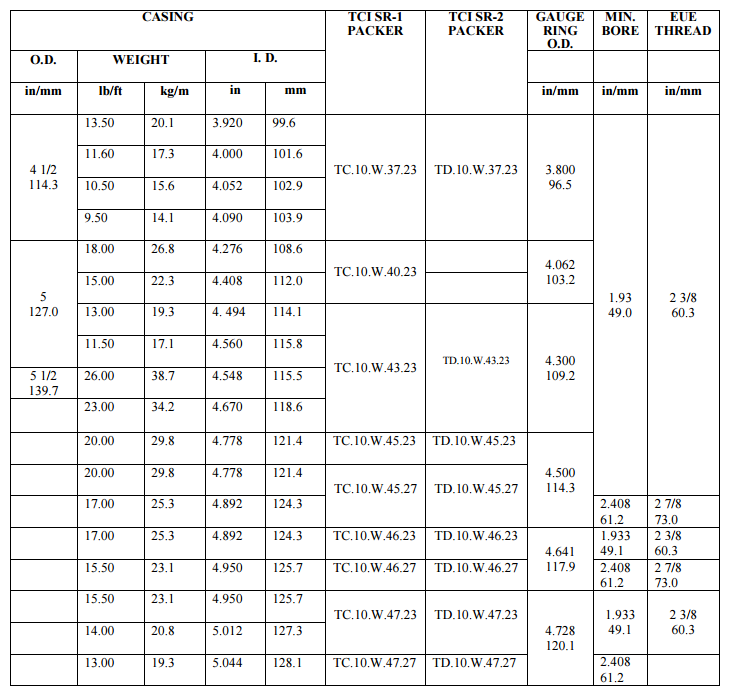

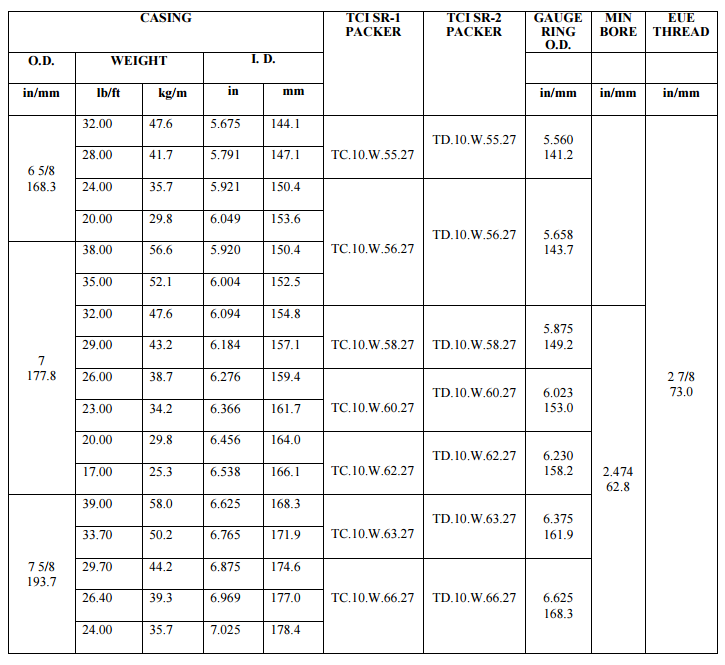

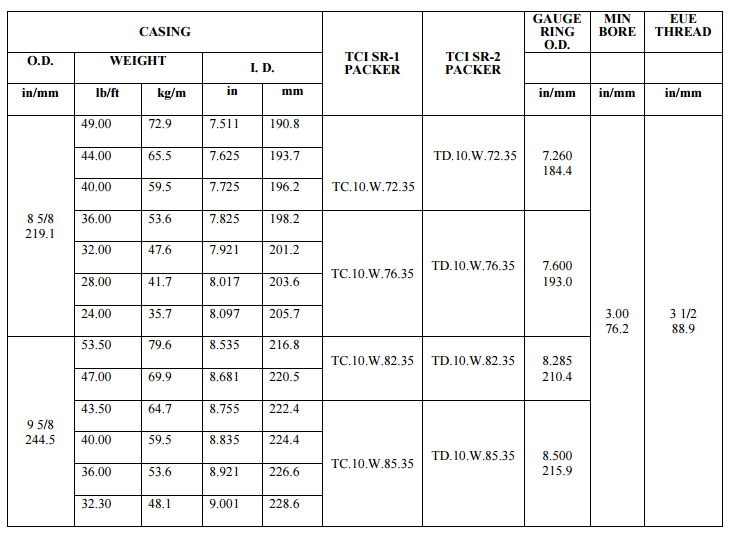

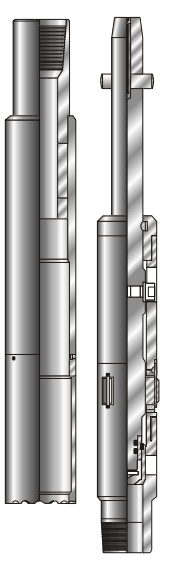

TCI SR-1 Retrievable Packer

The SR-1 Retrievable Packer is a versatile, full bore, double grip packer used for stimulation and production testing operations and is especially suited for applications in deep, high pressure wells.

This packer uses hydraulic hold down slips, operated by pressure from below the packer to secure the packer in place when high tubing pressures are encountered. A locking mechanism in the packer keepsthe By-Pass closed during high pressure injection operations

TCI SR-2 Retrievable Packer

TCI SR-2 Retrievable Packer

The SR-2 Retrievable Packer is used in applications where excessive bottom hole pressures or injection pressures are not expected, and sufficient tubing weight is available to keep the packer set. This packer is identical to the SR-1 except that it does not use the hydraulic hold down assembly

TCI Tubing Swivel

The TCI Tubing Swivel provides a safe means of rotating the tubing string while circulating with a treating line connected. It is primarily used in conjunction with the SST or Selective Tools, to provide a means of operating the By-Pass Valve while the treating line is connected.

It can also be used to facilitate the operation of other TCI Packers, or for light drilling.

When using this swivel, it is strongly recommended that the treating line be secured to the Tubing Swivel with a suitable safety chain or cable.

TCI Horizontal Well Stimulation Improves Production Using High Pressure Jetting Technology

Well Stimulation Overview

Oil inflow into the wellbore from unconsolidated sandstone reservoirs can be restricted in several ways. The restricting mechanisms can be difficult to identify and effectively treat. Heavy oil wells with long perforated liners also pose the challenge of low bottom hole pressure causing lost circulation during intervention. One of the first means of treating wellbore inflow problems is to apply an effective wellbore clean out program. TCI’s well cleaning technology effectively removes debris from the wellbore while also applying direct hydraulic jetting pressure to the open hole, casing wall and slotted perforations or screens.

Job Parameters

- 5 extended reach horizontal heavy oil injection and producing wells.

- Job design consisted of tubing lock up analysis, pump pressure calculations, tubing sizing, annular flow path pressure drop prediction and tool string design.

- Slotted Liner: 114mm and 139mm • Liner Tie Back String: 114 mm

- Vertical Depth: 480 m TVD

- Total Depth: 2300 mMD-2900 mMD

- BHP: 3,000 kPa -5,000 kPa

- Work over Fluid: Fresh Water

Results

- Production increase of 25 x.

- Nozzles maintaining original specification and Roturn-Jetting tool not requiring repair.

- Wells were “TD’d” in a field where getting to bottom has been a rare occurrence.

- Net volume of sand and asphaltene recovered greater than casing capacity.

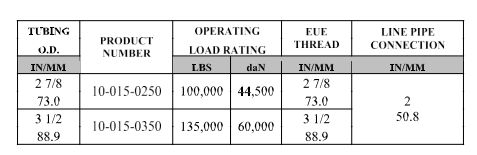

TCI B Hydraulic Setting Tool

The TCI B Hydraulic Setting Tool is used to run and set on Tubing, Coiled Tubing or Drill Pipe most packers which are normally set on wireline. It is especially applicable for use in deviated wells where it is not practical to run the tools on wireline or in situations where a Wireline Unit is not available.

The TCI B Hydraulic Setting Tool is used to run and set on Tubing, Coiled Tubing or Drill Pipe most packers which are normally set on wireline. It is especially applicable for use in deviated wells where it is not practical to run the tools on wireline or in situations where a Wireline Unit is not available.

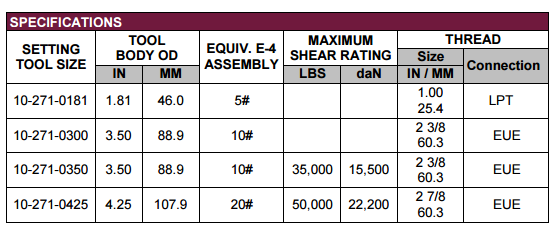

The B Setting Tool uses a bottom connection identical to the Baker E-4 Pressure Setting Assemblies. It is uniquely designed so additional piston sections may be added in order to lower the required setting pressure.

Operation:

This Setting Tool uses the same adapters for running as are used with a Baker E-4 Wireline Setting Tool.

The B Setting Tool is run into the desired setting depth and the ball is dropped to the ball seat in the tool. (When used on Coiled Tubing the ball is run in place). Sufficient pressure is applied to set and pack off the packer. The pressure or combination of pressure and tubing tension, then shears the Shear Stud or Ring, freeing the Setting Assembly from the packer. The Setting Tool will automatically drain the Tubing String as it is being pulled.

TCI Pump Tubing Bailer

The TCI Pump Tubing Bailer is a fast and efficient way to clean out sand or other fill from a well. It is an efficient mechanical pump capable of removing large volumes of fill in a single trip. The TCI Pump Tubing Bailer does NEED hydrostatic differential pressure in order to operate and WILL NEED to have some fluid circulation in extremely low fluid wells.

Large volume of sand or fill can be cleaned out in one trip. The debris chamber is adjustable to accommodate any amount of sand or fill to be retrieved. The bailer assembly is designed with circulating drain ports eliminating the pulling of wet strings.

A Spaded or saw tooth bit on bottom of assembly allows rotation through compacted sand.

Product Features:

- Heavy duty construction

- Operation simplicity

- Circulating drain valve eliminates wet strings

- Economical

- Cleanout can be accomplished in one run

Operation Procedures:

The TCI Pump Bailer Assembly is made up on the tubing string with the required amount of chamber between the pump assembly and the valve assembly. The pump assembly must be spaced out so that it will be below the fluid level in the well for it to operate properly. Once on bottom, the pump is stroked up and down. As the sand is pumped up into the fill pipe, it is necessary to move the pump assembly down so that the bottom of the pump is always contacting the top of the fill. If necessary, the assembly may be rotated. Continue this operation until either bottom is reached or the fill pipe is full (will stop making hole).

When pulling, the tubing will drain automatically

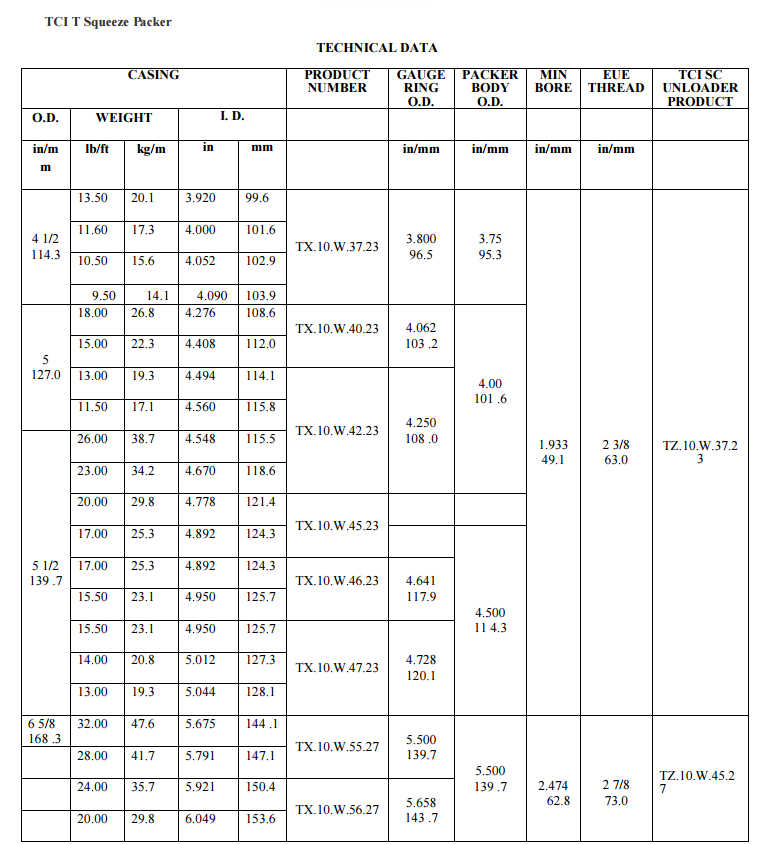

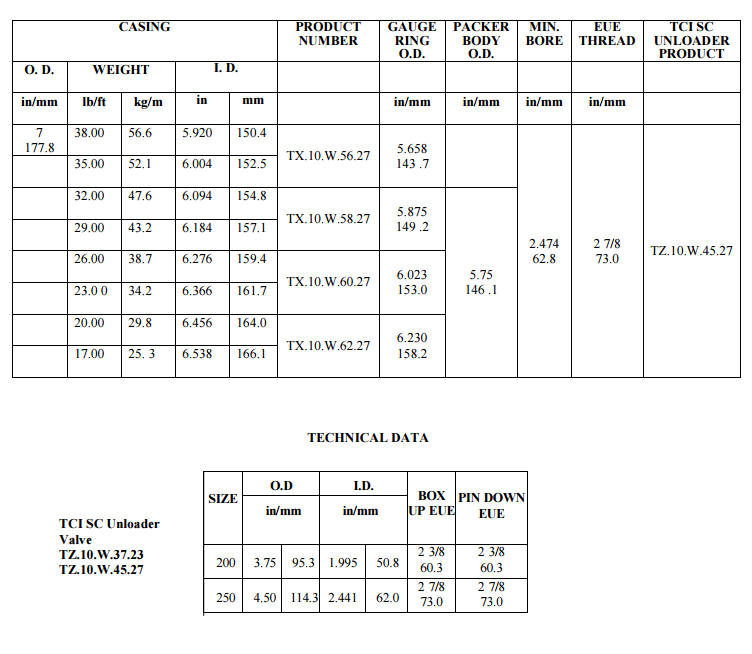

TCI SC Unloader Valve

The full bore SC Unloader allows equalization of tubing and annulus pressures when run in conjunction with the T Squeeze Packer. It is always recommended that this Unloader be used when running the T Squeeze Packer. Downward force opens the Unloader.

The full bore SC Unloader allows equalization of tubing and annulus pressures when run in conjunction with the T Squeeze Packer. It is always recommended that this Unloader be used when running the T Squeeze Packer. Downward force opens the Unloader.

TCI T Squeeze Packer

T he T Squeeze Packer is a full bore Tension Packer designed specifically for Squeeze Cementing, Acidizing, Testing or Fracturing operations. The use of this packer is especially desirable under conditions where the pressure differential is from below and the use of a Compression Packer is prohibited. The opposing slips enable the T Squeeze to remain packed off during pressure reversals.

he T Squeeze Packer is a full bore Tension Packer designed specifically for Squeeze Cementing, Acidizing, Testing or Fracturing operations. The use of this packer is especially desirable under conditions where the pressure differential is from below and the use of a Compression Packer is prohibited. The opposing slips enable the T Squeeze to remain packed off during pressure reversals.

This Packer uses a dependable three element system to reliably hold high pressures at high temperatures. A simple adjustment can convert the R-104 to left hand or right hand set. Normally the SC Unloader Valve is run in conjunction with the T Squeeze Packer to allow equalization of tubing and annulus pressures.

Considered the best tension set service packer available it is well suited for repeated and continuous use under the harshest of conditions.

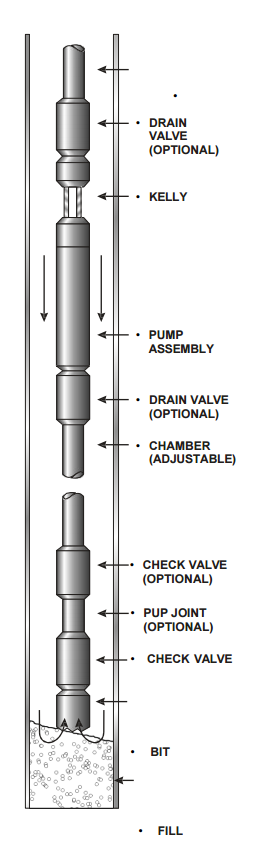

1. FLUID LEVEL: The bailer is a hydrostatic tool that operates by having an overbalance of fluid in the well.

1. FLUID LEVEL: The bailer is a hydrostatic tool that operates by having an overbalance of fluid in the well.

2. DRAIN VALVE: The Drain Valve allows the tubing to drain while tripping out.

3. KELLY: The Kelly provides the transmission of torque from the tubing string to the bit.

4. PUMP ASSEMBLY: Applied compression to the pump assembly opens the main valve and the annular overbalance forces the fluid and sand in through the bottom trap valves and up into the tubing chamber. The sand and debris collects in the cavity pipe above the valves, while the fluid goes through the pump assembly and is discharged into the tubing above.

5. DRAIN VALVE: The Drain Valve eliminate pressure build up in the adjustable chamber.

6. CHAMBER: The Chamber is made up of tubing to accommodate the amount of estimated fill.

7. CHECK VALVE: The Check Valve is of either flapper or ball design. The function of the valve is to maintain fill trapped in the adjustable chamber until surface is reached. The second Check Valve is run in case first Check Valve fails.

8. PUP JOINT: Space out Check Valves.

9. CHECK VALVE: As per item 7. JET SUB: TO HELP CLEAR FILL ON SUCTION OPTIONAL

10. BIT: Different bit types available dependent upon fill to be encountered.

11. FILL: Completion or maintenance sand, surplus frac-sand or debris where well cannot be circulated.

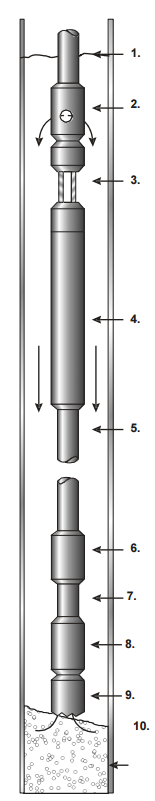

1. FLUID LEVEL: The Fluid Level must be maintained above the circulating valve for the pump tubing bailer to function correctly.

1. FLUID LEVEL: The Fluid Level must be maintained above the circulating valve for the pump tubing bailer to function correctly.

2. CIRCULATING VALVE: The valve has two functions with the first being of recycling of fluid during pumping operations. The second function is to drain tubing while tripping out.

3. KELLY: The Kelly provides the transmission of torque from the tubing string to the bit.

4. PUMP ASSEMBLY: Reciprocation of the pump assembly draws fluid and sand in through the bottom valves and up into the tubing chamber. The sand and debris collects in the cavity pipe above the valves, while the fluid goes through the pump assembly and is discharged into the annulus.

5. CHAMBER: The Chamber is made up of tubing to accommodate the amount of estimated fill.

6. CHECK VALVE: The Check Valve is of either flapper or ball design. The function of the valve is to maintain fill trapped in the adjustable chamber until surface is reached. The second Check Valve is run in case first Check Valve fails.

7. PUP JOINT: Space out Check Valves.

8. CHECK VALVE: As per item 6.

9. BIT: Different bit types available dependent upon fill to be encountered.

10. FILL: Completion or maintenance sand, surplus frac-sand or debris where well cannot be circulated.

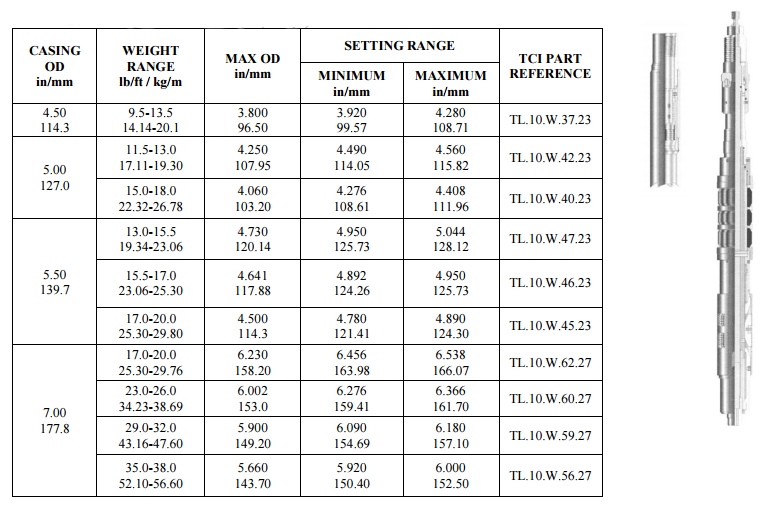

TCI SR-1/SR-2 Packer Technical Data