Flow Equipment

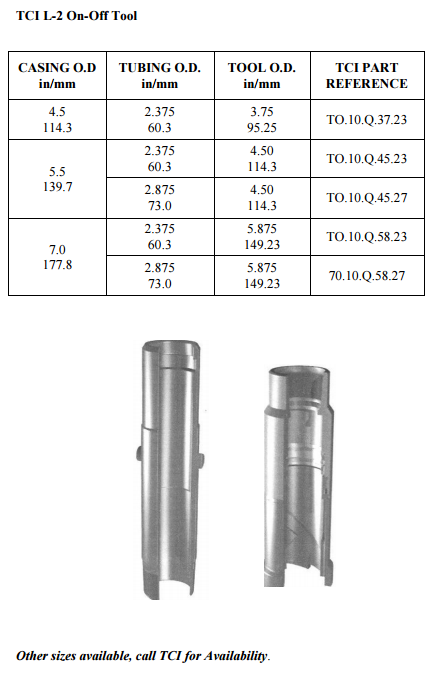

TCI L-2 On-Off Tool

The TCI L-2 is a tubing seal receptacle that allows the isolation of a lower zone using a wire line blanking plug. The tubing string can be disconnected and removed from the well. When the tubing is re- run the overshot portion of the tool automatically re engages on the slick joint, when landed.

Features:

- Blanking plug seats in the top of the slick joint to prevent build up of debris inside tools.

- Bonded seals for reliable sealing and disconnects / re-connects.

- Slick joint available with machined profile to accept any common wire line plugs.

- Overshot designed to allow for rotation through debris.

- J-slot provides for a positive connect or disconnect.

- Available with right or left hand release option.

- Designed to withstand pressure differentials up to (69000 kpa) 10000 psi

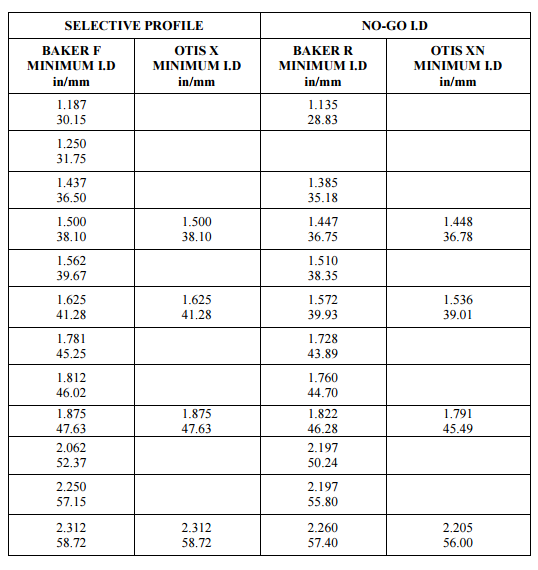

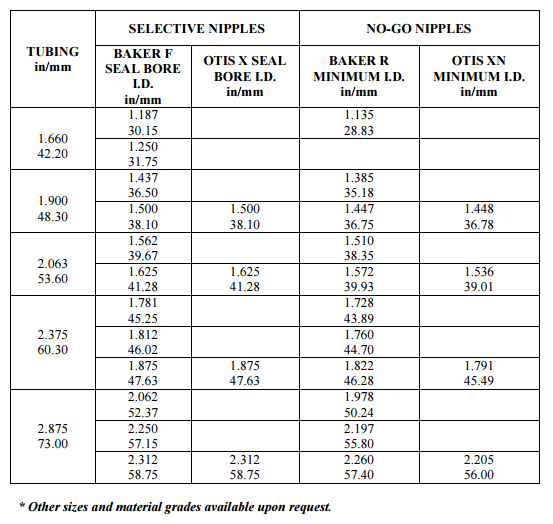

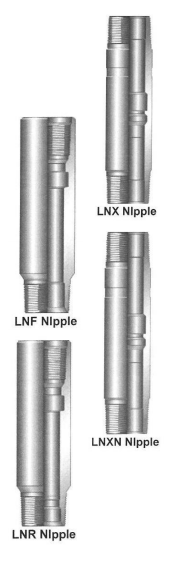

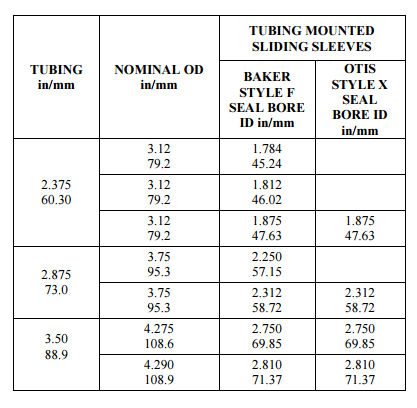

TCI Landing Nipples

The TCI landing nipples are profile subs that feature an internal seal bore and profile to accept a locking device to anchor flow control accessories. A variety of seal bores and lock profiles are available. Landing nipples are available full opening or with a no-go restriction to provide a positive stop for a flow control device. Landing nipple are sized to match tubing sizes and can be run above or below production packer systems to provide varying flow control options in the completion or production string.

Features:

- Nipples designed to accept common wire line flow control devices.

- Available in materials to suit a Variety of well conditions. L-80 materials are standard.

- Bores are honed to provide for optimum sealing.

- Frac hardening available upon request.

TCI Sliding Sleeves

The TCI sliding sleeve is installed in the production tubing string. The sleeve is a device that controls flow or movement of gas and wellbore fluids between the annulus and the tubing. An internal sleeve which is opened and closed using standard wire line procedures is utilized. Standard with the profile at the top and a polished bore below the communication ports.

Features:

- Available with a standard wire line profile

- Available in up opening and down opening configuration

- Multiple sleeves may be run in a single tubing string and opened/closed on a single wire line run

- Standard B shifting tool is used to open and closed the sleeve

- Standard material for H2S service

- Available as full bore (no profiles)

Purpose:

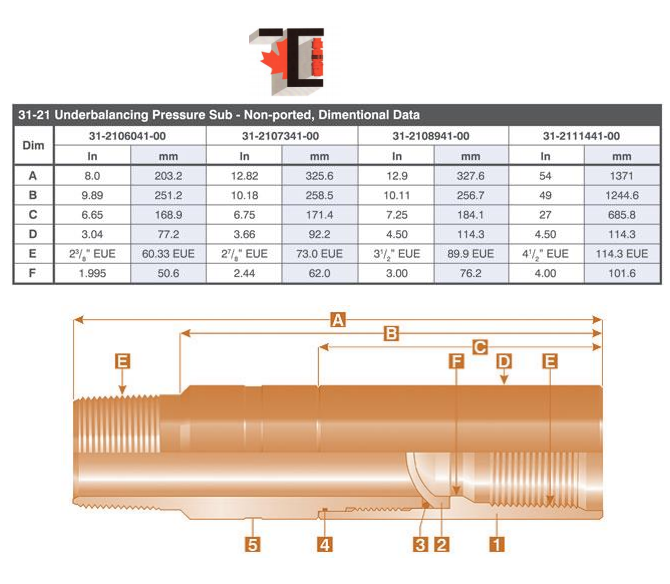

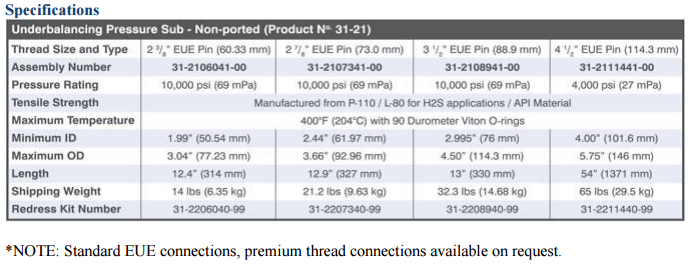

The TCI Burst Sub is used in a perforating system to provide an economical method of achieving an underbalanced condition between the tubing and wellbore formation. The tool incorporates a high strength ceramic dome which prevents communication between tubing and tubing / casing annulus until a detonating bar is dropped from surface. This tool can be used in other applications where the operator requires the formation to be surged after or during stimulation. This tool should not be used for snubbing operations.

Operation:

The non-ported Burst sub is installed in the tubing string normally above a packer to create the desired underbalanced condition. This tool prevents fluid from entering the tubing string above the packer, tubing maybe run completely dry or partly filled. When the operator is ready to detonate and fire the perforating the guns, a drop bar is released into the tubing from surface thus passing through the tool which shatters the ceramic dome, the drop bar continues on down the tubing string to fire the perforating gun(s) exposing the wellbore to this underbalanced condition.

TCI Tubing Tester

The TCI Tubing Tester Sub is designed to allow testing of the tubing string before beginning high pressure treatments, or before setting a Completion Packer.

It may be placed anywhere in the string and is treated like an ordinary Tubing Coupling or Cross Over Sub. When at depth, a Phenolic Ball is pumped down to the Tubing Tester and the tubing pressured up to the required test pressure. After testing the ball is reverse circulated out of the tubing and operations carried on as usual.

The Tubing Tester is available for all common tubing sizes.

TCI Pump Out Plug

The TCI Pump Out Plug may be used as a temporary plug to facilitate setting of hydraulic packers. The plug may be manufactured solid or with a hole and ball seat. A ball is dropped into a seat in the Pump Out Plug, and pressure applied on the tubing to set the packers and shear out the seat.

This Pump Out Plug is available in all common tubing sizes and threads, with either a Half Mule Re-Entry Guide down or with a pin down.